The Short Answer: You can reduce fire hose friction loss through proper hose selection, maintenance and the ideal deployment techniques. Things such as using the right hose diameter, maintaining clean surfaces and avoiding sharp bends are the main ways to reduce hose friction and keep your hose running optimally.

When water rushes through your fire hose, it’s constantly fighting against the inner walls. This creates friction loss – basically, you’re losing water pressure and flow between your pump and nozzle. And that pressure drop? It can seriously hurt your firefighting effectiveness, cutting down the reach and power of your water stream right when every second counts.

Understanding and preventing friction loss is a fundamental aspect of effective fire service and water delivery operations. Whether you’re a member of fire departments, industrial safety professional, or responsible for fire protection systems, knowing how to minimize friction loss helps maintain optimal flow rate and pressure when it matters most.

In this guide, we’ll explore:

- Practical strategies to prevent friction loss in fire hoses

- Factors that contribute to pressure drops

- Actionable steps to maintain optimal water flow performance

You’ll learn about proper hose selection, maintenance practices and deployment techniques that can make a real difference in water delivery efficiency.

The Friction Loss Basics

When water flows through a fire hose, it faces constant resistance that reduces its pressure and effectiveness. This resistance, known as friction loss, happens because water molecules rub against the inner surface of the hose and each other. Think of it like trying to push water through a straw – the longer or narrower the diameter, the harder it becomes to push the water through.

Water Flow and Surface Interaction

The inside surface of fire hoses, while smooth, creates drag as water flows past it. At higher flow rates, this effect becomes more pronounced. The water molecules closest to the hose wall move slower than those in the center, creating turbulence that requires more pressure to overcome.

Common Points of Friction Loss

Fire hoses experience the most significant friction loss because of these specific areas:

Couplings and Connections

- Create disruptions in smooth water flow

- Introduce resistance as water moves through different diameters

- Poor alignment or damaged threads amplify friction effects

Bends and Kinks

- A 90-degree bend is equal to adding 10-15 feet of straight hose length

- Force water to change direction quickly, creating turbulence

- Can compromise firefighting effectiveness through pressure drops

Hose Length

- Each additional 100 feet adds measurable friction loss

- More surface area contact between water and hose interior

- Compounds throughout the system, requiring careful pump pressure calculations

Measuring and Calculating Loss

Firefighters use standard friction loss calculations based on the hose diameter, flow rate (in gallons per minute) and length. These calculations help determine the required pump pressure to overcome friction loss and deliver adequate pressure at the nozzle. Pressure gauges at the pump panel and flow meters provide real-time feedback about friction loss in the system.

Smart Hose Selection and Setup

Selecting and setting up fire hose properly plays a major role in reducing friction loss. The right combination of hose diameter, layout and couplings can significantly decrease resistance to water flow and maintain proper pressure throughout the system.

Choosing the Right Hose Diameter

|

Hose Diameter |

Best Use Case |

Flow Rate |

Key Benefits |

|

1.75 inches |

Standard structural operations |

150-185 GPM |

Good maneuverability, acceptable flow |

|

2.5 inches |

Longer layouts, higher pressure needs |

250+ GPM |

Reduced friction loss, higher volume |

|

3+ inches |

Supply lines, large-scale operations |

500+ GPM |

Maximum flow, minimal friction |

Key Selection Factors:

-

Match the diameter to your specific flow requirements

-

Consider distance needs and operational constraints

-

Balance friction reduction with crew mobility requirements

-

Remember: larger hoses reduce friction but increase weight

Optimal Hose Layouts

Layout Best Practices:

- Keep your attack lines as straight as you can – every bend fights against you

- Skip unnecessary turns and twists that just create turbulence

- When you absolutely need a bend: make it gentle (at least 4x your hose diameter)

- Going uphill? Take the gradual route instead of steep climbs

- Plan your path ahead of time – think about what might get in your way

Elevated Operations Guidelines:

- Work with gravity, not against it – gradual slopes beat sharp angles

- Steep vertical runs are pressure killers

- Factor in gravity when you’re calculating pump pressure

Connection Best Practices

Coupling Essentials:

- Match your fittings – incompatible gear = trouble

- Thread everything correctly to stop leaks before they start

- Keep those coupling points clean – debris is a flow killer

- Make cleaning and checking couplings part of your routine

Multi-Length Connection Steps:

- Line up your hoses carefully – twists and kinks are your enemy

- Check those gaskets – cracked or missing ones will cost you pressure

- Keep everything watertight throughout your whole system

- Pro tip: Swivel adapters can save you when hoses want to twist

Maintenance and Prevention Strategies

Regular maintenance plays a direct role in preventing friction loss in fire hoses. A well-maintained hose allows water flow to move smoothly through its length, reducing unnecessary friction and pressure drops during firefighting operations.

Regular Inspection Routines

|

Inspection Area |

What to Check |

Frequency |

Red Flags |

|

Outer Jacket |

Abrasion, cuts, thin spots |

After each use |

Exposed liner, deep cuts |

|

Couplings |

Thread damage, loose connections |

After each use |

Bent threads, loose fit |

|

Gaskets |

Wear, proper seating |

Weekly |

Cracks, missing pieces |

|

Internal Condition |

Mineral buildup, debris |

Monthly |

Restricted flow, blockages |

Documentation Requirements:

- Record all inspection findings

- Track hose performance over time

- Identify patterns indicating emerging problems

- Schedule preventive maintenance based on findings

Proper Cleaning Methods

Clean hoses thoroughly after each use to prevent friction-causing buildup. Wash the outside jacket with clean water and a soft brush, moving from one end to the other to remove dirt and contaminants. For internal cleaning, flush the hose with water at moderate pressure. Once cleaned, hang the hose to dry naturally – avoid direct sunlight or heat sources that can damage the material. Only store hoses when completely dry to prevent mildew growth that could affect water flow.

Damage Prevention

Protect the fire hose during active use by avoiding sharp edges and rough surfaces when deploying. Use hose bridges when crossing roadways to prevent crushing damage that can create internal friction points. When transporting hoses, roll them properly using the recommended donut roll or flat load techniques. Store hoses in clean, dry areas away from chemicals, oils and extreme temperatures. Stack them on proper racks or shelves to prevent crimping or folding that could create permanent deformations, leading to increased friction loss.

Implementing A Friction Loss Prevention Plan

Preventing fire hose friction loss comes down to implementing several proven strategies. Regular hose inspections, proper hose line laying techniques and choosing the right hose diameter for your flow requirements form the foundation of an effective prevention plan. Following the maintenance schedule, avoiding sharp bends and keeping couplings properly aligned can reduce friction loss by up to 30%.

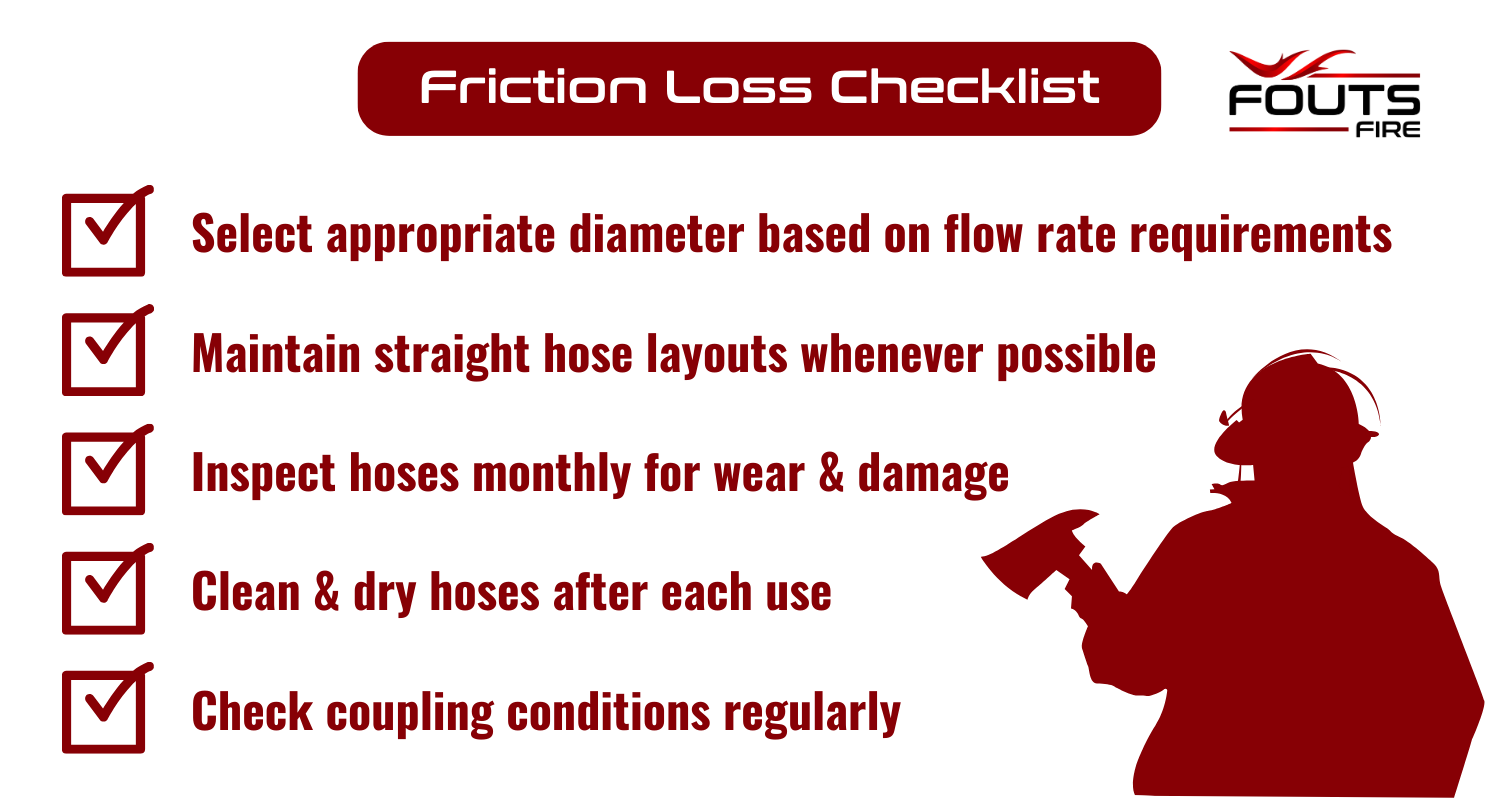

Here’s your quick friction loss prevention checklist:

- Inspect hoses monthly for wear and damage

- Maintain straight hose layouts whenever possible

- Select an appropriate diameter based on flow rate requirements

- Clean and dry hoses after each use

- Check coupling conditions regularly

These prevention methods enable faster water flow and maintain consistent pressure when it matters most. For optimal friction loss prevention in your fire hose system, consult with experienced fire service specialists who can evaluate your specific needs and recommend appropriate solutions.

Ready to enhance your department’s firefighting capabilities? Contact Fouts Fire today to get your fire apparatus needs solved!