At a Glance: Class C fires are caused by damaged or malfunctioning energized electrical equipment, including faulty wiring, poor installation, and overloaded outlets. Unlike other fire types, Class C fires can cause electrocution, making them very hazardous to fight without proper knowledge and equipment.

Class C fires are electrical fires involving equipment like household appliances, power tools, industrial machinery, and computer systems. In the United States, almost 7% of residential and nonresidential fires were caused by electrical malfunction in 2023, and they cause significant rates of injuries, deaths, and property damage every year. Understanding these fires is essential for workplace safety and home protection since many of these incidents are preventable with proper knowledge, regular maintenance, and safety protocols.

Understanding Class C Fires

The fire classification system categorizes fires based on their fuel source so firefighters and safety professionals can use the appropriate suppression methods.

- Class A Fires: Involve ordinary combustibles like wood, paper, and cloth.

- Class B Fires: Involve flammable liquids and flammable gases, such as gasoline, oil, and solvents.

- Class C Fires: Involve energized electrical equipment.

- Class D Fires: Involve combustible metals like magnesium and sodium.

- Class K Fires: Involve vegetable oils, fats, and other cooking oils used in commercial kitchens.

Electrical fires are classified separately because they require specialized suppression techniques. The presence of electricity creates unique hazards that make traditional firefighting methods, particularly water, extremely dangerous. Water conducts electricity, meaning spraying water on an electrical fire can result in electric shock.

Class C fires differ from every other type of fire in several ways. They can originate inside walls, electrical panels, or equipment where fires remain hidden until they’ve spread significantly. They often create multiple ignition points as electricity arcs through systems.

Once power is disconnected, a Class C fire technically becomes a Class A or B fire. However, during active burning with electricity still flowing, these fires still need special handling.

Common Causes of Class C Fires

Electrical System Failures

Electrical system failures are the leading cause of Class C fires.

- Overloaded Circuits: If too many devices draw power from a single circuit, it can generate excessive heat.

- Short Circuits: These happen when electrical current takes an unintended path due to damaged insulation or improper connections, creating intense heat and sparking.

- Electrical Arcing: This generates temperatures exceeding 35,000 degrees Fahrenheit, which can instantly ignite nearby combustible materials.

- Faulty Wiring: Whether from age, physical damage, or poor installation, this damage creates resistance that generates dangerous heat.

- Loose Electrical Connections: These produce heat at outlets, switches, or wire junctions

- Degraded Wire Insulation: This allows conductors to contact each other or grounded surfaces, triggering fires.

Equipment Malfunctions

Defective appliances and electronics can develop internal faults that cause overheating and ignition.

- Motor Failures: Electrical components can overheat when bearings fail or windings short-circuit.

- Extension Cord Failures: Overloading, physical damage, or using undersized cords generate dangerous heat and can cause the cord to fail.

- Battery Charging Issues: Overcharging or using incompatible chargers have become increasingly common fire causes since lithium-ion batteries are more commonly used in consumer electronics.

Improper Installation and Maintenance

- DIY Projects: Electrical work performed without proper knowledge frequently violates electrical codes and creates serious fire hazards.

- Code Violations: Non-compliant installations may work initially but contain hidden dangers that manifest over time.

- Lack of Regular Inspections: Not completing electrical inspections can allow problems to develop undetected over time.

- Outdated Systems: Failing to update systems means older wiring designed for lower electrical loads now serves modern buildings with much higher power demands.

- Incompatible Electric Components: Mixing components creates dangerous conditions that may not be immediately noticeable.

Settings at Highest Risk

Certain environments face elevated Class C fire risks:

- Commercial Kitchens: These contain numerous electrical systems operating continuously under demanding conditions.

- Data Centers: Since server rooms pack dense concentrations of electrical equipment, they generate significant heat.

- Manufacturing Plants: Industrial facilities with heavy machinery experience vibrations and stresses that damage electrical systems over time.

- Older Buildings: Outdated electrical systems weren’t designed for modern electrical loads and are more likely to become overloaded.

- Aging Wiring: Residential homes built before 1970 may contain deteriorating systems with insufficient capacity.

Common Risks and Hazards

Electrocution Dangers

The primary hazard distinguishing Class C fires is the risk of electrocution. During firefighting efforts, anyone attempting to suppress an electrical fire faces potential electric shock if they contact energized equipment or use conductive suppression agents like water-based extinguishers. Higher voltages create danger zones extending farther from the source, requiring greater safety distances. Other injuries from electrical contact include falls, cardiac arrest, and severe burns.

Fire Spread Characteristics

Electrical fires spread differently compared to other fire types. They can travel through wiring systems behind walls and above ceilings, reaching distant locations before becoming visible. This hidden fire travel can quickly overwhelm firefighting efforts, making electrical fires very dangerous.

Property and Equipment Damage

Class C fires can cause significant damage beyond direct fire destruction, especially in industrial settings.

- Expensive electrical systems and equipment may be completely destroyed even by relatively small fires.

- Smoke and soot damage extends far beyond the fire area, potentially ruining electronics throughout a building.

- Business interruption and downtime costs accumulate rapidly when electrical fires shut down operations.

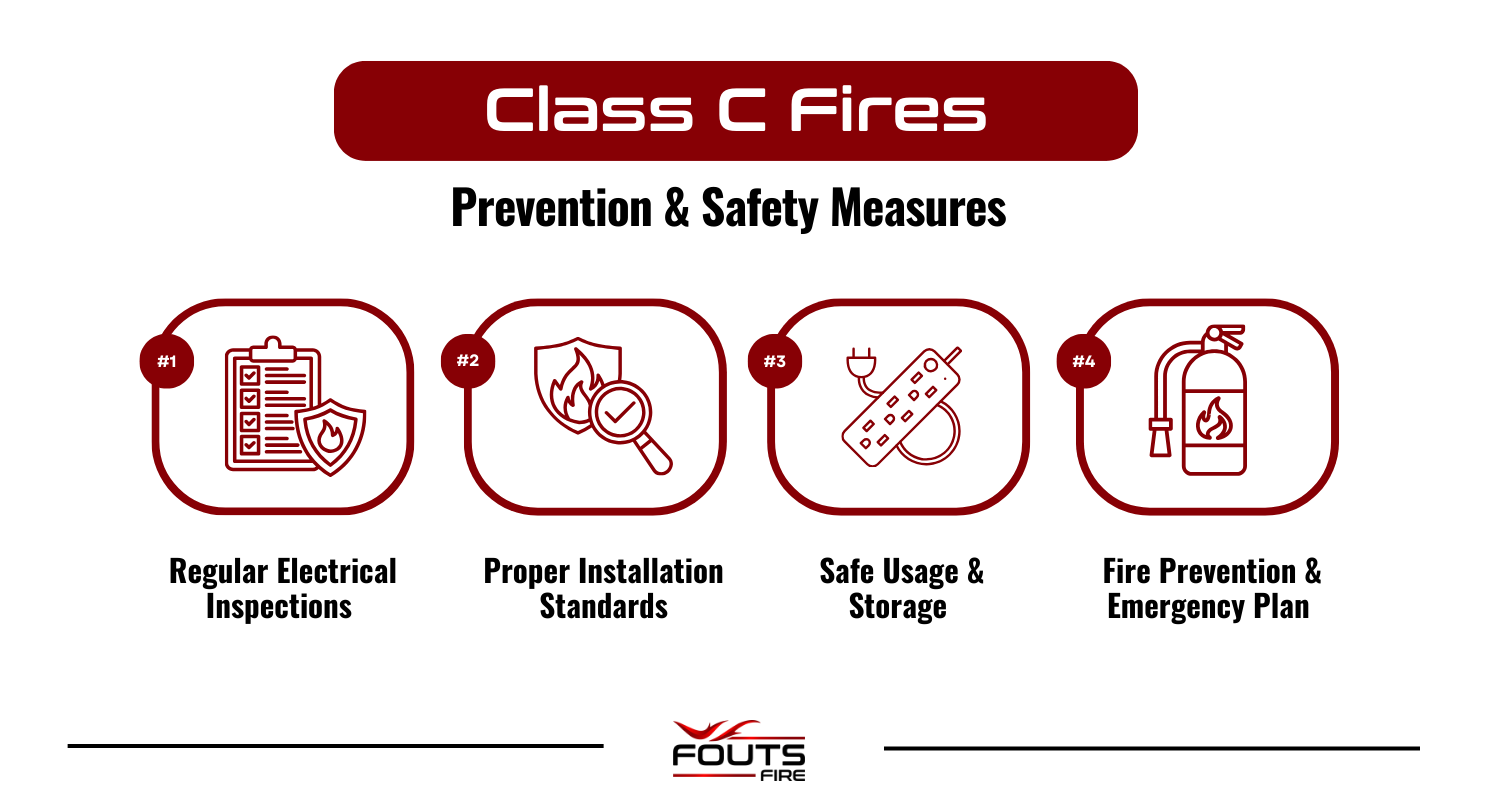

Safety & Prevention Methods

Regular Inspections and Maintenance

Scheduling professional electrical inspections provides the foundation for Class C fire prevention.

- Residential properties should receive inspections every 3-5 years

- Commercial and industrial facilities may require more frequent evaluations depending on equipment and use.

- Electrical inspectors should examine wiring strength, connection tightness, panel conditions, proper grounding, and circuit loading.

- Equipment maintenance should follow manufacturer recommendations for cleaning, connection tightening, and component replacement.

Proper Installation Standards

- Hiring Licensed Electricians: This ensures that all electrical work and installations meet code requirements and safety standards.

- Following Set Requirements: The National Electrical Code (NEC) provides current best practices for safe installations.

- Using Appropriate Equipment: The right wire gauges and circuit ratings are matched to expected loads to prevent overheating.

- Installing Electrical Protection: Ground Fault Circuit Interrupter (GFCI) protection in wet locations and Arc Fault Circuit Interrupter (AFCI) protection in living areas provides automatic shutdown when dangerous conditions develop.

- Using Proper Grounding: This ensures fault currents trigger protective devices rather than creating fire hazards.

Safe Usage Practices

Understanding circuit capacity means knowing how much power each circuit can safely handle and not exceeding those limits.

- Extension cords should be used temporarily and must be rated for connected equipment’s power requirements.

- Electrical appliances should be unplugged when not in use.

- Electrical equipment should be kept away from water.

- Three-prong plugs should never be forced into two-prong outlets.

Warning Sign Recognition

Recognizing electrical problem warning signs allows intervention before fires develop.

- Burning smells near outlets or appliances indicate overheating.

- Frequent circuit breaker trips could be a sign of overloaded circuits or equipment faults.

- Flickering lights suggest loose connections.

- Discolored outlets or switch plates show heat damage.

- Sparks or buzzing sounds indicate arcing.

- Warm outlets or electrical panels signal dangerous heat buildup.

Taking immediate action when these signs appear prevents many electrical fires.

Response and Fire Safety

Immediate Response to Class C Fires

When discovering a Class C fire, you should:

- Cut power at the breaker if you can safely reach the electrical panel. Never use water on energized electrical fires due to electrocution risks.

- Use only Class C or ABC-rated fire extinguishers.

- Only attempt to fight small, contained fires when you have proper equipment and a clear escape route.

- Electrical fires spread rapidly through hidden pathways, so always call emergency services immediately.

Class C Fire Extinguisher Requirements

CO2 extinguishers work well on Class C fires involving sensitive equipment because they leave no residue, though fires may reignite. Dry chemical extinguishers offer general-purpose protection but leave residue that can damage electronics.

All extinguishers should be accessible within 75 feet of potential electrical fire sources. For businesses, all employees working with or near electrical equipment should receive hands-on training for emergencies.

After the Fire

Following any electrical fire, have systems professionally inspected before power restoration. Document all damage thoroughly for insurance claims. The root cause should be identified and corrected to prevent another fire.

Protecting Yourself From Class C Fires

Class C fires pose unique dangers requiring specialized knowledge for prevention and response. Understanding electrical fire risks, recognizing common causes, and implementing comprehensive prevention methods significantly reduce incident likelihood. Regular professional electrical maintenance, safe usage practices, and immediate attention to warning signs form the foundation of effective prevention.

For more safety information, the National Fire Protection Association (NFPA), Occupational Safety and Health Administration (OSHA), and local fire departments can offer resources. You can also protect your property by scheduling an electrical inspection and ensuring fire suppression systems are properly rated for electrical fires.

Find Fire Apparatus Solutions at Fouts Fire

No matter what type of fire they’re facing, having the right equipment is crucial for fire departments. At Fouts Fire, we offer a variety of fire apparatus models that are designed to help firefighters meet their community’s needs. Find a Fouts Fire dealer near you to find out how our proven fire apparatus solutions can help your department handle whatever emergencies lie ahead.